It is effective for fast measurement and correction of the profile thickness of sleeve films during the extrusion process in real time.

- IMPROVING FILM QUALITY

- FAST RETURN ON INVESTMENT

- STABLE RESULTS

- HIGH ACCURACY OF FILM PROFILE CORRECTION

- MARKET LEADING SPEED OF THICKNESS TOLERANCE CORRECTION

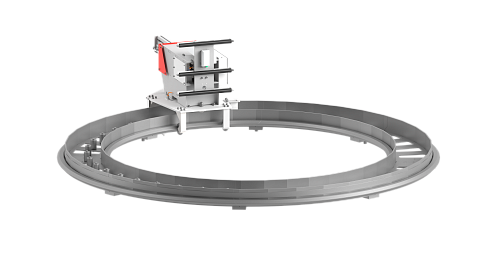

The system is designed for quick measurement and automatic correction of profile thickness on blown films lines during the real time extrusion process.

-

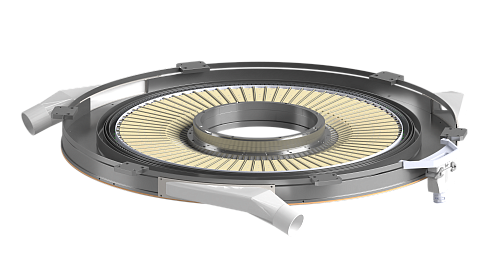

CONTINUOUS CONTROL OF FILM PROFILE. Thickness measurement is performed non stop at the angle of 360 degrees.

-

KUNDIG SENSOR. Continuous measuring and online data processing is made by system based on a Kundig sensor (Switzerland)

-

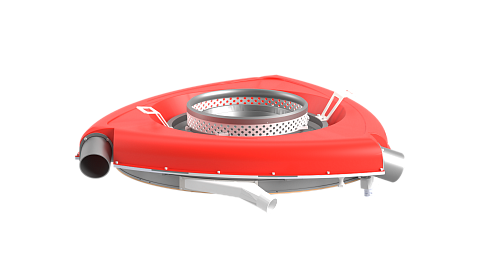

THE OUTER SURFACE IS MADE OF COMPOSITE MATERIAL WITH FIBERGLASS REINFORCEMENT. It prevents condensation on the inner surface of the system

-

COMPLETE INSULATION:

- between air ring and die head

- between each heating elements

by using innovative aerogel material -

DUST PROTECTED

The fully protected design prevents any mechanical contamination -

FAST AND PRECISE CORRECTION

Stand-alone zones for thickness profile correction of blown films. The number of zones makes the adjustment process more accurate and faster -

CLEAR DATA REPORTING

Native software:

- Full reporting on function processes

- Data reporting in digital and percentage values -

FRIENDLY CONTROL

22 inches color screen with informative interface

| ДИАМЕТР ГОЛОВЫ | КОЛИЧЕСТВО ЗОН КОРРЕКЦИИ |

| 180-300 мм | 56 |

| 310-450 мм | 72 |

| 460-600 мм | 96 |

ПОКАЗАТЕЛЬ 2 СИГМА (2о) УМЕНЬШИЛСЯ С 5,68% ДО 1,51% ВСЕГО ЗА 6 МИНУТ, А С 9,04% ДО 1,90% ЗА 10 МИНУТ

Такая оперативность позволяет быстрее и с меньшими потерями переходить от одной ширины/толщины пленки к другой.