Description

Equipment:

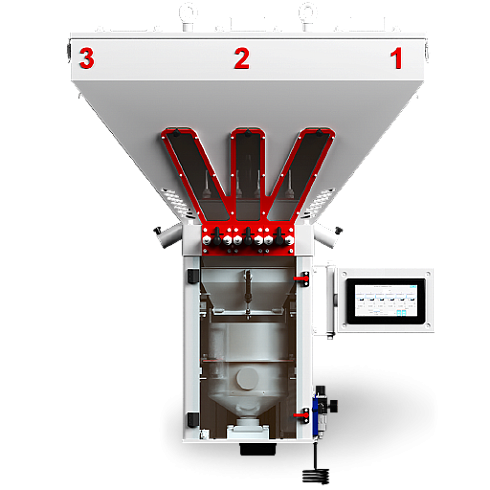

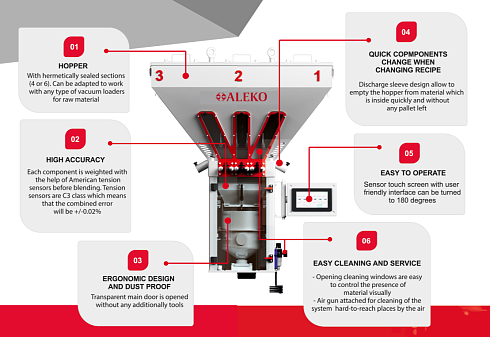

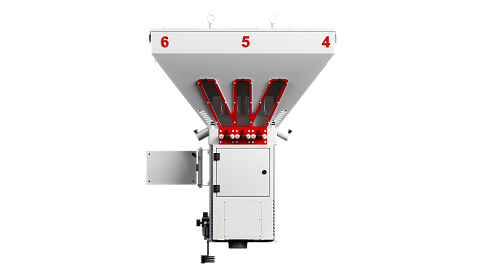

- Hopper

With hermetically sealed sections (4 or 6). Can be adapted to work with any type of vacuum loaders for rw\aw materials. - Quick components change when changing recipe

Discharge sleeve design allow to empty the hooper from material which is inside quickly and without any pallet left. - Ergonomic design and dust proof

Transparent main door is opened without any additionally tools. - Easy cleaning and service

- Opening cleaning windows are easy to control the presence of material visually

- Air gun attached for cleaning of the system hard-to-reach places by the air - High accuracy

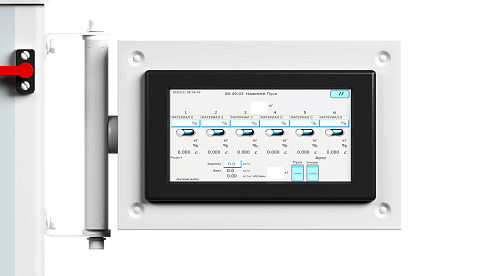

Each component is weighted with the help of American tension sensor before blending. Tension sensors are C3 class which means that the combined error will be +/- 0,02% - Easy to operate

Sensor touch screen with user friendly interface can be turned to 180 degrees.

Standard control function:

- Control of uo to 6 components

- 3 levels of users

1. User

2. Technology engineer

3. Experts

With the possibility to control access - Different ways to enter recipe. Each component content can be entered both in percent or in grams.

- Material identification. Letters and figures qwerty key-pard for exact identification of materials.

- Production process tracking in display. Each operation of recipe, set and actual data and speed of the process are shown in display

- Recipe saving. Internal memory for up to 1000 recipe

- Number of batchers counting. Dosing until will turn off automatically after reaching set number of batchers.

- Self optimiation. Independent adjustment of dosing parameters to change the flow of different materials.

- "Stay on" function. Recipe and parameters could be changed without stopping the system.

- Standard reports.

- cycle - weighing parameters: time if discharge gate opening, number of repeat attempts, weight in the first attempt

- consumption - each hour report about each component and total material consumption

- possibility to make a report as per the user request

- Possibility for remote control. Ethernet protocol Modbus TCP

- Power. 220/380 V, depend on customer request

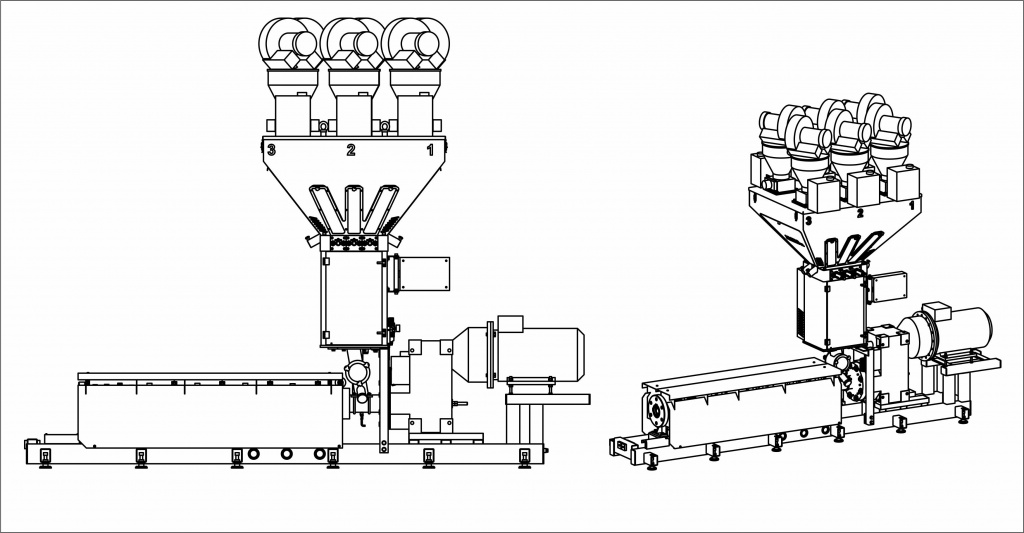

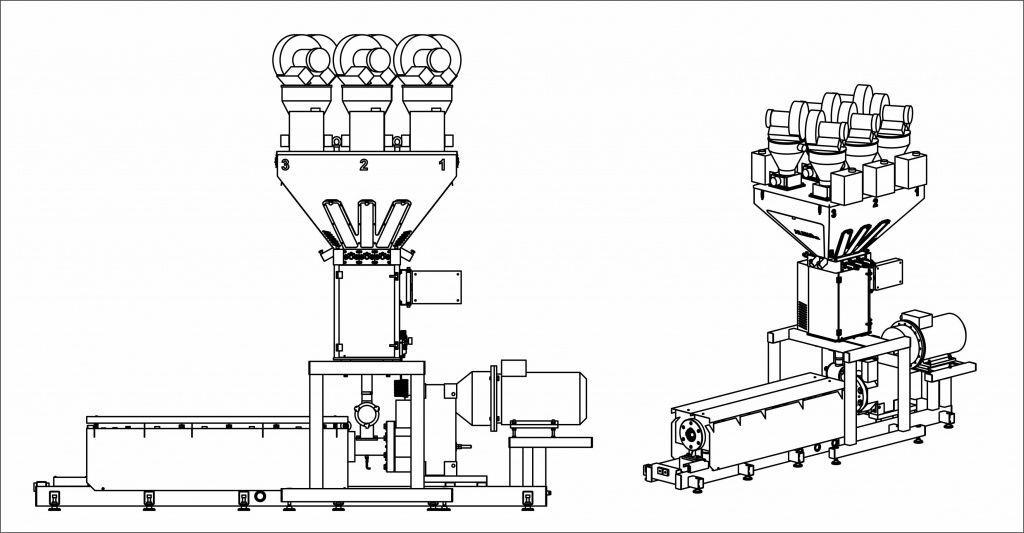

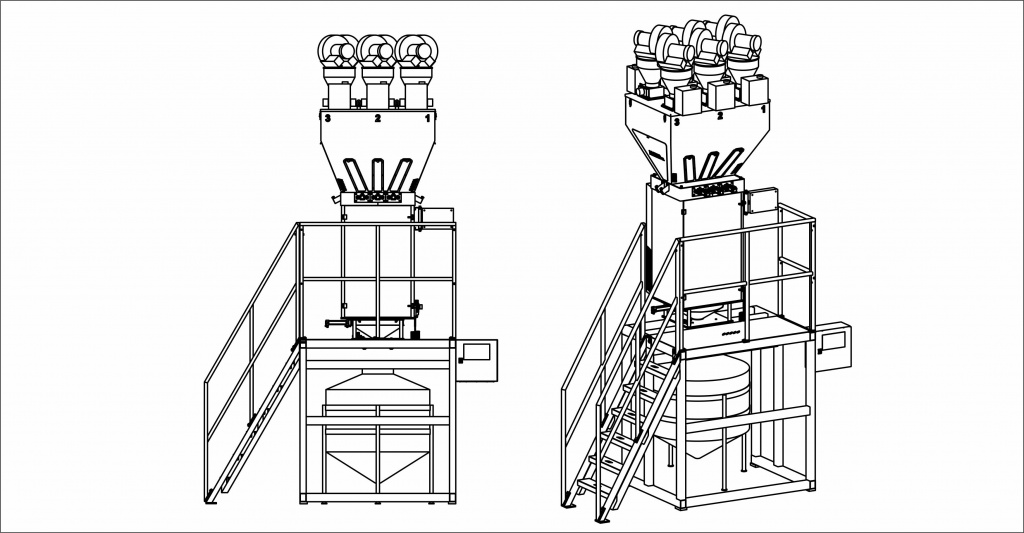

Installation options:

Dosing system on the press

Dosing system on a stand on the press

Dosing system with pneumatic bottle for working on capacity

Additional options:

- Extrusion control

Mixer scales measure the material consumption in a set periodof time. Operator set desired weight of the running meter of the film or the pipe or the other product. Dosing system will calculate required for this weight capacity of the screw. After this the system will maintain needed screw r.p.m. depending on material consumption. As a result the weight of ready product will be maintained stable

- MAGNET RODS

A device to catch accidentally fall into the raw material metal particles which can be stopped by magnet (black metal particles, metal shavings)/ This will prevent technological equipment from damage

- RAW MATERIAL VACUUM LOADERS

It is possible to equip dosing system with material supply vacuum loaders or we can make connections as per customer vacuum loaders connection size.

Advantage:

- Precise dosing

- One batch dosing accuracy up to 0,04% (one batch = 100 kg)

- 100% control over material consumption

- After each closing door opening or closing the weight of the batch will be corrected

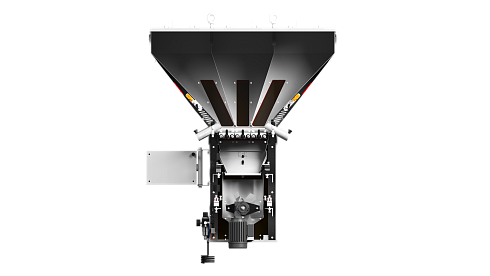

- Uniform and eficient materials blending

- Mixer hopper design guarantee the absence of material stacking points

- The shape of mixer blades ensure efficient and uniform material blendingФорма бункера миксера гарантирует отсутствие точек "зависания" материала

-

Sensor displey with convenient interface- Components content is entered both in grams and in percentage

- You can change recipe without stopping the blender

- Memory up to 1000 recipe

- You can limit the number of batches

- Display can be in any language

- Diagonal 7". Resolution 800*480 pixels

Characteristics

|

PARAMETER |

GR 150 | GR 300 | GR 500 | GR 1000 |

|---|---|---|---|---|

| Number of components | 4/6 | 4/6 | 4/6 | 4/6 |

| Production capacity* (kg/h) | 150 | 300 | 500 | 1000 |

| Dosing accuracy (% for a batch 100 kg) | to 0,04 | |||

| Weight of one batch of material (kg) | 1 | 2 | 5 | 10 |

| Volume of weighing hopper (l) | 5 | 6 | 10 | 20 |

| Volume of mixer hopper (l) | 10 | 27 | 35 | 70 |

| Number of load cells | 4 | |||

| Dimensions L x W x H (mm) | 1106*878*1277 | 1106*878*1427 | 1106*878*1937,5 | 1106*878*2017 |

| Weight (kg) | 195 | 240 | 440 | 500 |

| Power, kW | 220/380 V, 50 Hz | |||

*average value; actual throughput may vary and depends on the material

Video

Дополнительные опции:

- Функция управления экструзией

Весы миксера постоянно измеряют расход сырья в единицу времени. Оператор задает желаемый вес погонного метра продукции - пленки или трубы, например. Дозатор рассчитывает необходимую для этого веса производительность шнека экструдера. Далее дозатор поддерживает необходимую производительность, следовательно и вес погонного. метра, регулируя скорость шнека и вытяжного устройства.

- Магнитный уловитель

Устройство для улавливания случайно попавших в сырье металломагнитных примесей и различных включений из чёрного металла (фрагменты, стружка, частицы черного металла, и т.п.). Предотвращает повреждение технологического оборудования

- Загрузчики сырья

Возможна комплектация загрузчиками/системой подачи материала сразу на производстве или изготовление креплений под размеры загрузчиков заказчика, согласно техническому заданию.