Description

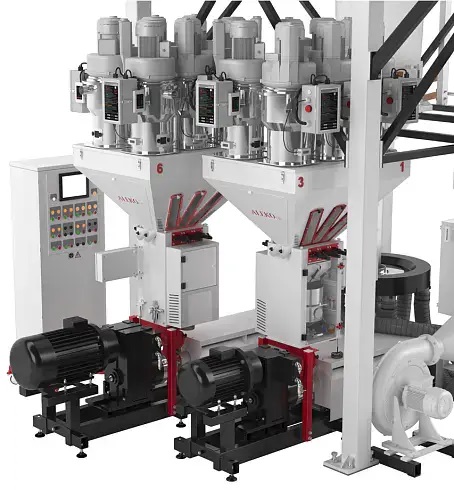

Blown film line «Aleko Bio» can recycling it is capable of processing modern biodegradable polymers based on polylactic acid (PLA), as well as biopolymers obtained from corn or potato starch.

Without losing the quality of the film, "Aleko BIO" gives a capacity of up to 220 kg/hour on 65 augers, with a head diameter of 200 mm, which is a unique indicator in the market for the production of biodegradable films.

The machine is universal.

Despite the fact that the auger is designed for biodegradable raw materials, it can also be used for processing LDPE.

A screw was designed specifically for this machine, which carefully processes bio-raw materials without overheating it, so that the resulting film has a much higher elasticity and strength.

Without losing the quality of the film, "Aleko BIO" gives a capacity of up to 220 kg/hour on 65 augers, with a head diameter of 200 mm, which is a unique indicator in the market for the production of biodegradable films.

The machine is universal.

Despite the fact that the auger is designed for biodegradable raw materials, it can also be used for processing LDPE.

BIOFEEDSTOCK SCREW WITH BIMETALLIC COATING

Characteristics

|

Parameter |

BIO 1100/65 |

|---|---|

| Materials | Bio/LDPE |

|

Width of film, mm |

1100 |

|

Film thickness, mcm |

8-50 |

|

Screw diameter, mm |

65 |

|

Capacity, kg/h |

220 |

|

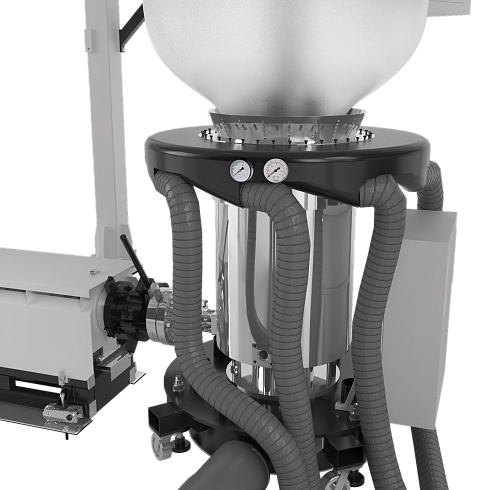

Filter Type |

Candle |

|

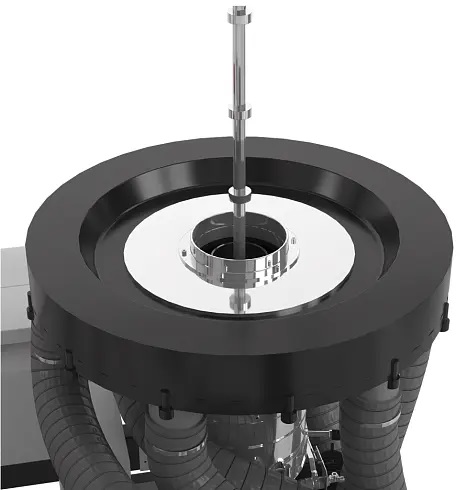

Die head type |

200 (with rotation) |

|

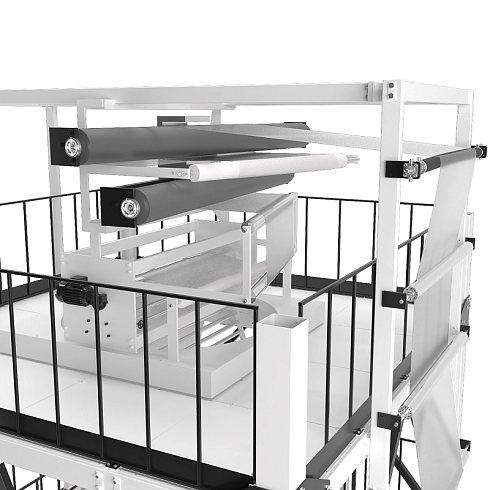

Stabilizing basket unit |

Roller with lifting device |

|

Film edge position control |

Center position control (CPC) |

|

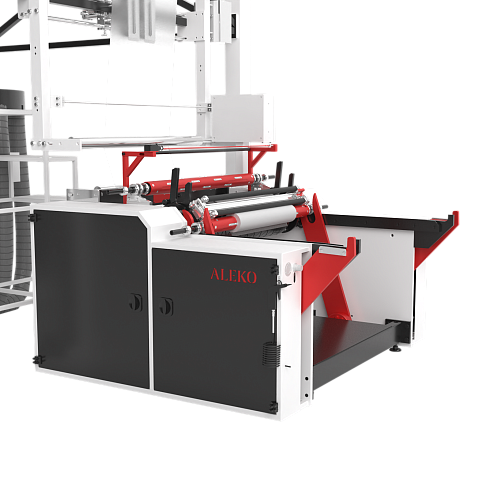

Winder type |

Single-post / double-post - auto |

|

Main motor power, kW |

45 |

|

Dosing system |

Gravimetric dosing system Aleko GR300 with extrusion control option, 6 components. |

|

Control system |

PLC controller with touch screen display. System control and diagnostic via remote access |

|

Height, m |

7,2 |

Video

We recommend

Air shaft

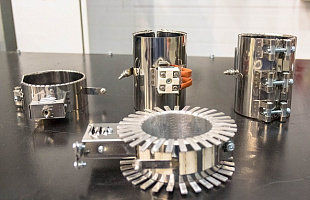

Heating elements

Screw