Description

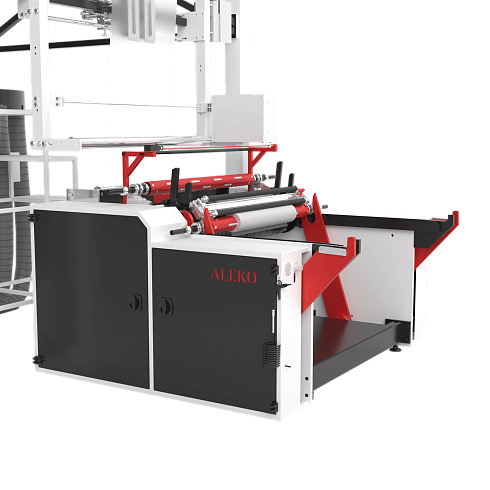

High speed HDPE extrusion line for the production of thin HDPE films

One of the few machines in the world capable of stable operation at high speeds.ALEKO TURBO

- Line speed - up to 200 m/min

-

Film thickness - from 5 mcm

Advantages:

- High capacity

- Low thickness tolerance up to +7%;

- High mixing abilities doe to screw features

- Stable work at thin 6 mcm films

- Specially developed design of screw, die head and blower ring allows to produce thin HDPE films from 5 microns without reducing productivity (up to 140 kg/hour).

- Unlike other similar equipment, "ALEKO Turbo" maintains stable high speed even on inexpensive HDPE brands

- Thanks to the servos on the exhaust, intermediate pulling and winding devices, stable operation of the line at high speeds (200 m/min) is ensured, as well as high torque at low speeds

- The ring head with an increased number of channels provides high throughput and productivity (up to 140 kg/h) with a head diameter of 100-120 mm

- Inverters, thermal controllers "Delta", Taiwan

Characteristics

| Model | TURBO 1100/60 |

|---|---|

|

Materials |

HDPE |

|

Sleeve width, mm |

1100 |

|

Film thickness, mcm |

5-40 |

| Type screw | L/D 1/32, barrier compression |

|

Screw diameters, mm |

65 |

|

Capacity, kg/h |

to 120 |

|

Maximum speed, m/min |

to 220 |

|

Die head type |

with rotation |

|

Die head diameter, mm |

125 |

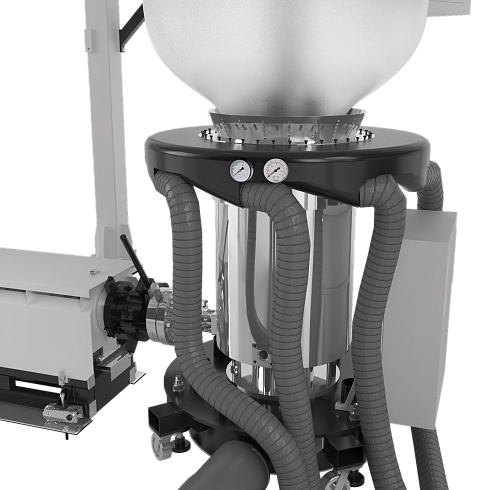

|

Air cooling ring |

Aluminium double-slot |

|

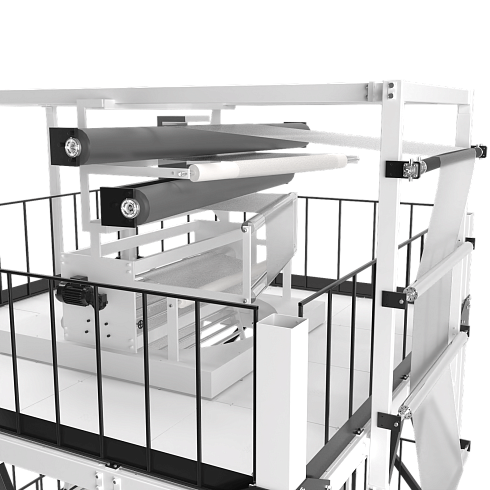

Stabilizing basket unit |

Roller, with up and down mechanism |

|

Film edge position control |

Center position control (CPC) |

|

Winder type |

Single-post (two-post - optional) |

|

Roll change |

Automatic |

|

Type of drive for "exhaust device", "intermediate pulling unit" and "winding mechanism" |

Servomotor (3 pcs) |

|

Dosing system |

Gravimetric dosing system Aleko GR150 with extrusion control option, 6 components |

|

Control system |

PLC controller with touch screen display. System control and diagnostic via remote access |

|

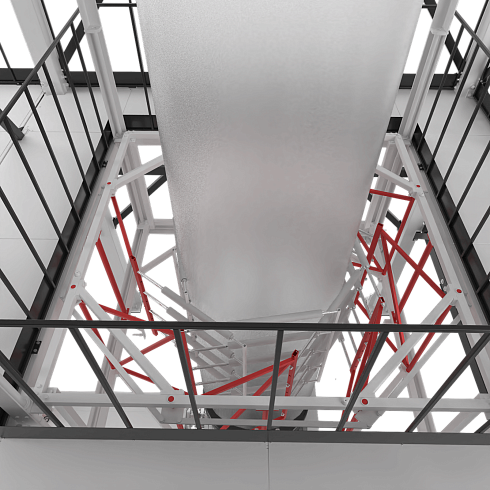

Height, m |

8,7 |

Video

We recommend

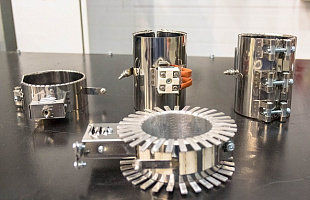

Candle Filter

Heating elements

Screw