Description

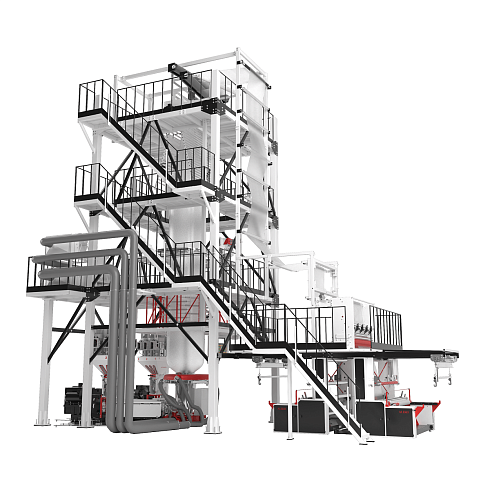

Multilayer АВC / ABCDE - multilayer blown film lines

manufactured by the company "Aleko", Russia

Processed materials:- LDPE, HDPE, LLDPE, mLDPE, PA, EVA, EVOH, и т.д.

- lamination film

- barrier film

- film for freezing

- milk film

- Shrink film

- Courrier bag film

- All series of Aleko blown film machines are fitted with high-performance screws which are manufactured under license of Plamex Company, (Germany)

- The screws have a complex geometric shape, which makes it possible to achieve high performance and efficient blending

- Our screw work well on recycled materials and cases when good level of homogenization of hard mixing polymers is required.

Liners:

-

Screw cylinders are technically designed with an integrated feed section

Feed section with helical grooves (flutes)

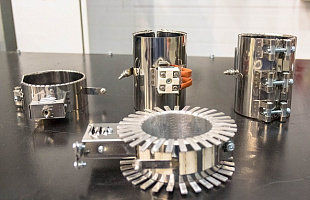

Heating: ceramic and mica heaters

Cooling: axial-flow fans

-

Horizontal rotating device: width 1500-2100 mm

Vertical rotating device: width 800-1300 mm

- Thickness tolerance up to ±1,5%

-

Compression type with two barrier zones and one mixing zone

Made of steel with bimetallic coating

Diameters: 45/55/65/65/75/90 at customer's option

- Gearboxes of all Aleko series are designed for high loads.

- Bearings and gear wheels are lubricated by immersing in oil. Oil cooling is made via heat exchange unit

- Main bearing is integrated in gear case, which provides constant lubrication

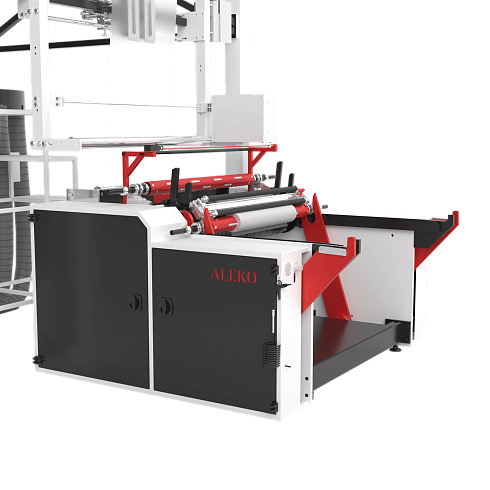

- Possibility to be equipped with single station winder or double station back-to-back type winder. All winders are contact type with tension control system, EPC system can be installed optionally

- Optimal polymer rheology

- Short channels for material flow

- Temperature maintenance

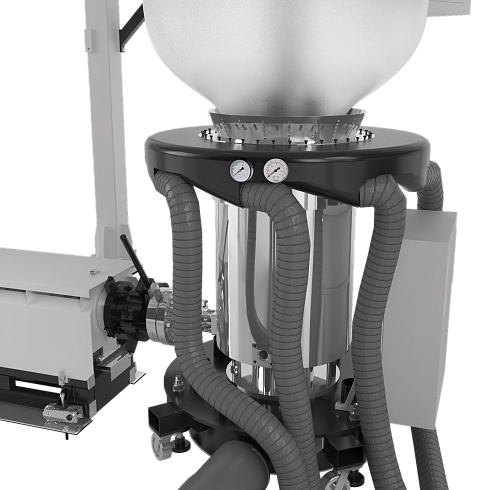

- Effective system of air inlet for IBC

- Working surface with hard chrome plating (thickness 30 mcm)

- Thermal insulation of each layer

- Possibility of changing the number of layers (up to 9 layers)

- Possibility of quick cleaning of the die head

- Series can be equipped with the following diameters of the die heads: 250/300/350/400/500/600 at the customers needs

-

Two-slot adjustable blower ring with point adjustment feature

Internal cooling system (IBC)

- PLC controllers are used with TOUCH SCREEN

- Control of heating elements with the use of PID control

- Remote control via Internet access

- All electric motors have "Delta" inverter control

- Machines of Aleko multilayer series are equipped with manual tope or hydraulic type screen changers.

Characteristics

| Model | 55/65/55 | 65/75/65 | 75/35/75/35/75 | |

|---|---|---|---|---|

| Materials | LDPE,LLDPE,HDPE, mLDPE, EVA | LDPE,LLDPE,HDPE, mLDPE, EVA | mLLD, LDPE, EVA, Tie, PA | |

| Capacity, kg/h | 360 | 450 | 650 | |

| Thickness of film, mkm | 20-200 | 20-200 | 20-200 | |

| Screw diameter, mm | 55+65+55 | 65+75+65 | 75+35+75+35+75 | |

| Screw L:D ratio | 1/32 | |||

| Filter Type |

valve filter (with manual / hydraulic changeover) |

valve filter (with hydraulic changeover) | valve filter (with hydraulic changeover) | |

|

Die head type |

stationary | |||

|

Wind-up roll diameter, mm |

to 500 | |||

| Layer ratio | up 1/1/1 to 1/3/1 | up 1/1/1 to 1/3/1 | up 2/1/2/1/2 to 6/1/6/1/6 | |

|

Effective film width, mm |

1700 | 2100 | 2100 | |

|

Die head diameter, mm |

300-450 | 350-500 | 350-500 | |

|

Rotation turret |

yes |

yes |

yes |

|

|

Die gap, mm |

1,2-2,2 | 1,2-2,2 | 1,2-2,2 | |

| Height, m | 11,6 | 11,6-13,6 | 11,6-13,6 | |

|

Type of winder |

Single-post / two-post |

|||

|

Roll removal |

Automatic/manual |

|||

| Main motor power, kW | 30/45/30 | 45/55/45 | 55/11/55/11/55 | |

|

Power consumption, kWh |

145 | 178 | 230 | |

|

kW consumption per 1 kg of production, kW/kg |

0,3-0,4 | |||

Video

We recommend

Air shaft

Heating elements

Screw