The system is designed for accurate, continuous dosing of granular material fed into the loading zone of extrusion lines.

-

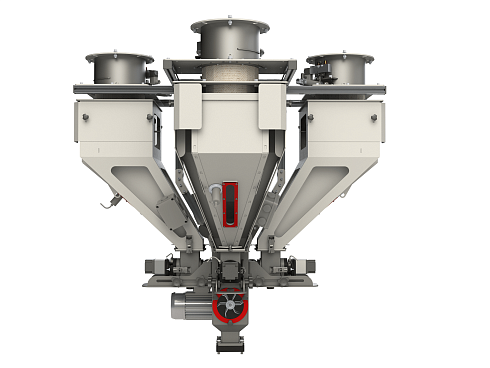

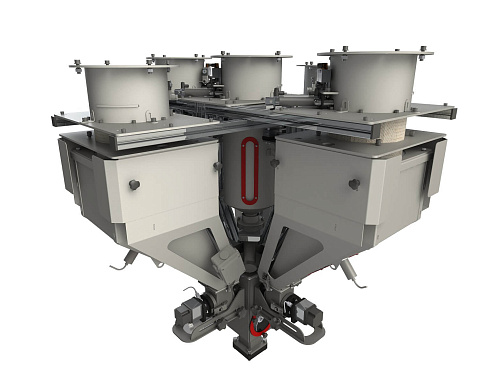

The system is capable of dosing up to 5 different components of granular materials

It can be installed on single/multi-layer extrusion lines.

The material is dosed by means of interchangeable screws of three different sizes with their own capacity value.

The material to be dosed is fed from the silo/raw material tank into the weigh hopper by a vacuum feeder. A pneumatic damper is installed between the vacuum feeder and the weigh hopper.

The weigh hopper has 2 strain-gages and is filled up in cycles. When the pneumatic damper is opened, the hopper is filled from 4 to 8 kg. After that the pneumatic damper gets closed.

Before being fed into the loading zone, the material is mixed one more time in the mixer hopper to obtain a more homogeneous mixture of components.

From this point on, the system starts counting and regulating the feed material, providing that values of the initial portion and the actual material flow rate are known.

The control system has its own controller that allows calculations to be made to accurately dose each component. The dosage value for each component is entered manually by the operator or is taken from the system memory for a saved recipe.| Модель | GRS 1+1 | GRS 1+2 | GRS 1+3 | GRS 1+4 |

|---|---|---|---|---|

| Двигатель (квт) | 0,2 | 0,2 х 2 | 0,2 х 3 | 0,2 х 4 |

| Производительность (кг/ч) | 0,06 - 40 | 0,06 - 40 | 0,06 - 40 | 0,06 - 40 |

| Объем бункера основного материала (л) | 10 | 10 | 10 | 10 |

| Объем бункера дополнительного материала (л) | 9 | 9 | 9 | 9 |

|

Пневмозаслонка между вакуумным загрузчиком и бункером |

2 | 3 | 4 | 5 |

| Объем бункера миксера (л) | 3,5 | 3,5 | 3,5 | 3,5 |

| Количество тензодатчиков | 4 | 6 | 8 | 10 |

| Габариты ДхШхВ (мм) | 460х840х970 | 840х840х970 | 840х1220х970 | 1220х1220х970 |

| Вес (кг) | 115 | 165 | 212 | 260 |

| Питание | 3ф., 380в. | 3ф., 380в. | 3ф., 380в. | 3ф., 380в. |