Description

High-performance extruders for the production of wide-format LDPE film

The MAXI series includes four machines with high productivity and maximum possible sleeve width.

Equipped with screw modules:- Ø 65 = up to 180 kg/h

- Ø 75 = up to 250 kg/h

- Ø 90 = up to 300 kg/h

- Ø 100 = up to 350 kg/h

- Shrink bundling film (pallet and multi-unit packaging)

- Greenhouse plastic film

- Construction film

- Technical films

- Agricultural film

- High capacity

- Low thickness variation up to ±7%;

- Low energy consumption 200 kVt/h;

- High mixability of material due to screw features

- Customization of the extrusion line to meet specific customer requirements

- Compression screws with two barrier and two mixing zones made of wear-resistant alloys with bimetallic coating

- Control and diagnose might be managed by remote access

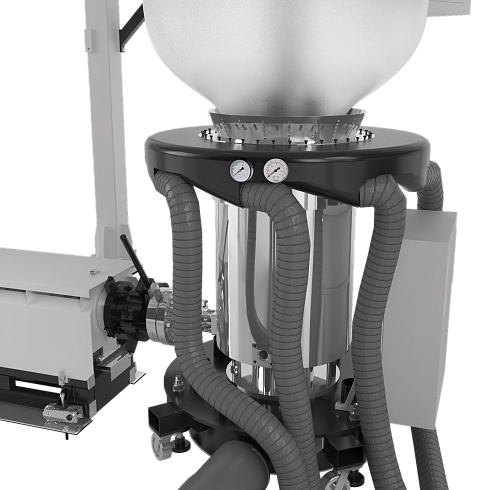

- Double-slot aluminum blower ring with fine adjustment

- Main drive gearbox with low noise, ground helical gears with cooling system

- Melt pressure sensors

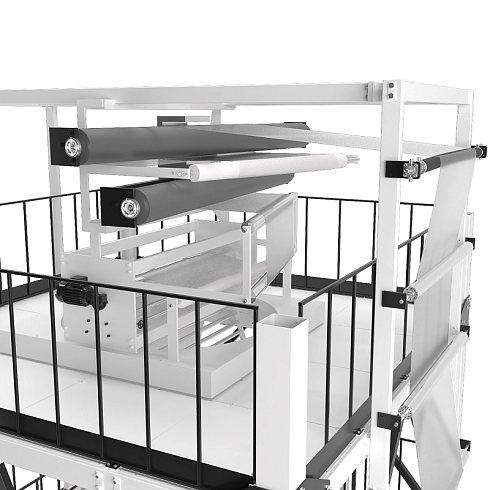

- EPC or CPC edge position control

- Control of web tension

- Inverters, "Delta" temperature controller, Taiwan

Characteristics

| Model | 1500 | 1700 | 2100 | |

|---|---|---|---|---|

| 65 | 65 | 75 | 75 | |

| Materials | LDPE, LLDPE, mLDPE | |||

|

Capacity, kg/h |

to 180 | to 250 | ||

|

Film thickness, mcm |

0,025-0,25 | |||

|

Screw diameters, mm |

65 | 75 | ||

|

Screw L:D ratio |

1/32 | |||

|

Filter Type |

Valve (with manual / hydraulic changeover) | |||

|

Die head type |

Stationary / with rotation |

|||

|

Diameter of winding roll, mm |

700 | |||

|

Effective film width, mm |

1500 | 1700 | 2100 | |

|

Die head diameter, mm |

250/300/350/400/500 | |||

|

Rotating turret |

option | |||

| Die gap, mm | 1,2 - 2,4 | |||

|

Height, m |

to 11,6 | |||

|

Winder type |

Single station/ double station | |||

|

Roll removal |

Automatic/manual | |||

|

Main motor power, kW |

45 | 55 | ||

|

kW consumption per 1 kg of production, kW/kg |

0,4-0,5 | |||

Video

We recommend

Air shaft

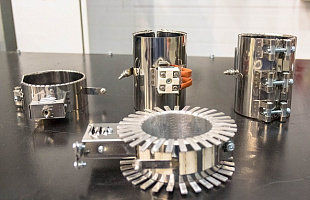

Heating elements

Screw