Description

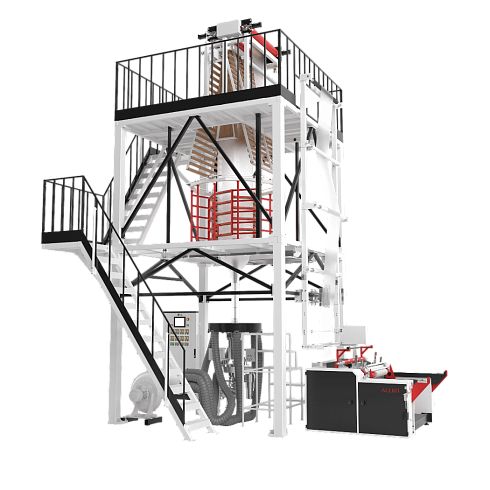

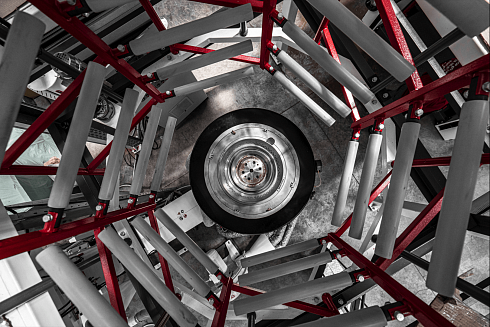

Blown film machines "Aleko Midi" for LDPE or HDPE

The MIDI series includes four models with different tolerances of maximum sleeve width.

The extruders are equipped with screw modules:- Ø 55 HDPE = up to 120 kg/h

- Ø 55 HDPE = up to 90 kg/h

Scope of application:

-

film for medical applications;

-

garbage bag;

-

shopping bag;

- shrink bundling film for multi-unit packagingApplication:

-

High productivity;

Low thickness variation up to ±7%;

Low power consumption up to 0.37 kW/kg;

High mixability of the material due to the features of the screw;

Small size. Customization of the line to meet specific customer requirements;

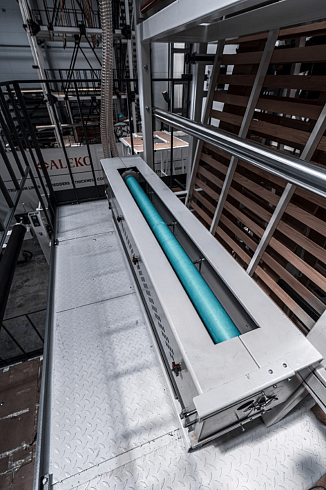

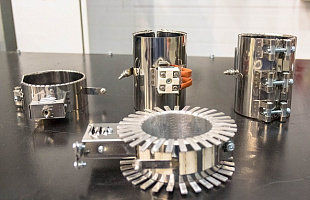

Double-slot aluminum blower rings;

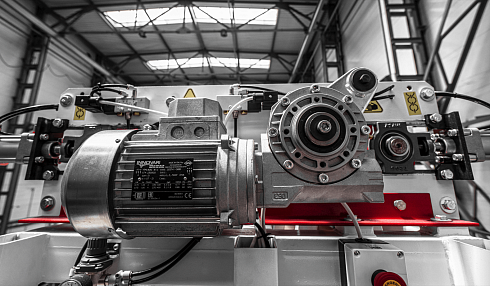

Main drive gearbox with low noise, ground helical gears with cooling system;

Inverters, "Delta" temperature controller, Taiwan

Characteristics

| Model | HDPE 1100/1300-55 | HDPE 1100/1300-55 |

|---|---|---|

| Materials | HDPE | LDPE, LLDPE, mLDPE |

|

Capacity, kg/h |

to 90 | to 120 |

|

Film thickness, mcm |

0,006-0,04 | 0,025-0,2 |

|

Screw diameters, mm |

55 | |

|

Screw L:D ratio |

1/32 | |

|

Filter Type |

Candle/valve | |

|

Die head type |

stationary/with rotation |

|

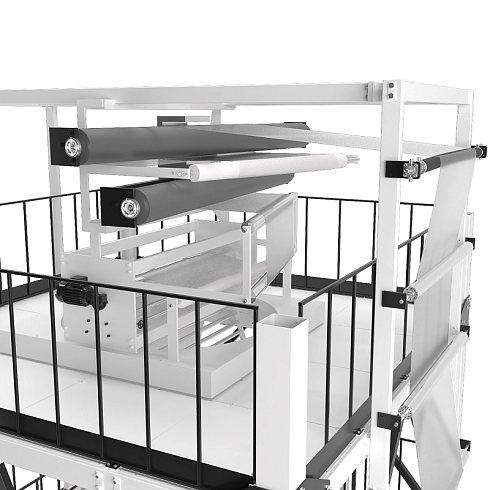

| Wind-up roll diameter, mm | 700 | |

| Effective film width, mm | 1100/1300 | |

|

Die head diameter, mm |

80/100/125/150 | 150/200/250/300 |

| Die gap, mm | 0,8-1,8 | 1,4-2,0 |

|

Height, m |

6,6/7,8 | |

|

Type of winder |

Single station/ double station (back to back) | |

|

Roll removal |

Automatic/manual |

|

|

Main motor power, kW |

30 | |

|

Power consumption, kW/h |

50 | |

Video

We recommend

Air shaft

Heating elements

Screw