Description

Extruders for the production of LDPE or HDPE film.

The MINI series includes four models.

The machine is characterized by its small size with a high level of PRODUCTIVITY and COST-EFFECTIVENESS.

The extruders are equipped with screw modules:- Ø 45 HDPE = up to 70 kg/h

- Ø 45 HDPE = up to 65 kg/h

- Ø 55 HDPE = up to 120 kg/h

- Ø 55 HDPE = up to 90 kg/h

- T-shirt bag

- Filling bag

- Garbage bag

- Hig capacity

- Low thickness variation up to ±7%;

- Low energy consumption up to 0,37 kW;

- High mixability of material due to screw features

- Compact size

- Steady operation for thin films from 6 mcm

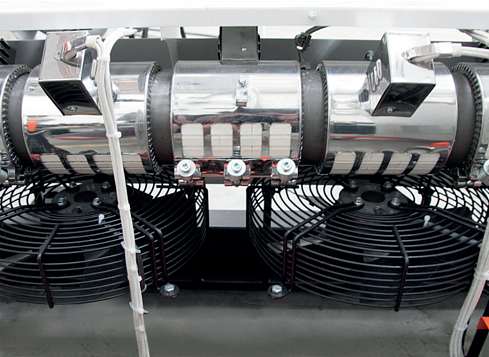

- Main drive gearbox with low-noise, ground helical gears with cooling system

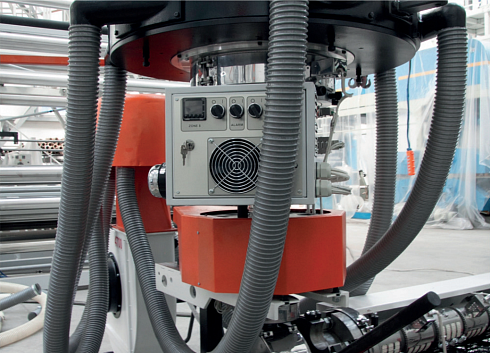

- Double-slot aluminum blower ring

- Inverters, "Delta" temperature controller, Taiwan

Characteristics

| Model | HDPE 8ОО-45/55 | LDPE 800-45/55 |

|---|---|---|

| Material | HDPE | LDPE |

|

Capacity, kg/h |

to 65/90 | to 70/120 |

|

Film thickness, mcm |

0,006-0,04 | 0,025-0,16 |

|

Screw diameters, mm |

45/55 | |

|

Screw L:D ratio |

1/32 | |

|

Filter Type |

candle/valve | |

|

Die head type |

stationary/with rotation |

|

|

Diameter of the wind roll, mm |

700 | |

|

Effective film width, mm |

800 | |

|

Diameter die, mm |

40/50/80/100 | 100/125/150 |

| Die gap, mm | 0,8-1,4 | 1,4/1,6 |

|

Height, m |

4,8/6,6 | |

|

Winder type |

Single station/ double station (back to back) |

|

|

Roll removal |

Automatic/manual |

|

|

Main motor power, kW |

18,5/30 | |

|

kW consumption per 1 kg of production, kW/kg |

0,3-0,4 | |

Video

We recommend

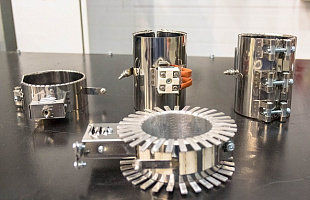

Candle Filter

Heating elements

Screw