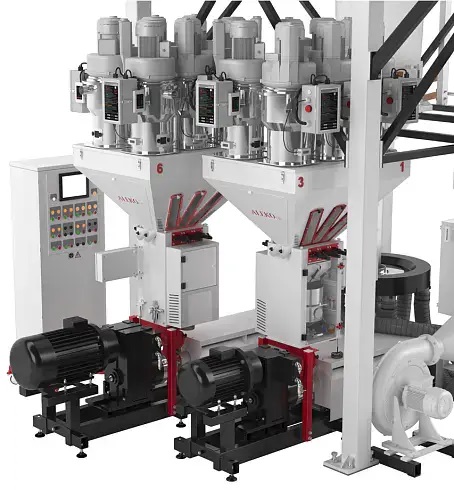

Multilayer АВА - multilayer blown film lines

manufactured by the company "Aleko", Russia

- LDPE, HDPE, LLDPE, mLDPE, fillerCaCO3 и т.д.

- T-SHIRT BAG

- SHRINK BUNDLING FILM

- PACKAGING FILM

- GARBAGE BAG

Advantages of Aleko ABA compared to single-layer lines:

-

Reduced production costs by introducing up to 100% recycled raw materials or up to 70% CaCO3 based chalk compound in the middle layer (B) of the film

Layer ratio up to 1/8/1

Preservation of marketable appearance of products due to outer (A) layers made of primary raw materials, reliably covering the middle (B) layer.

Improved physical and mechanical properties compared to a single-layer film of the same material due to the use of a three-layer structure.

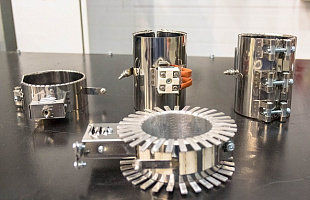

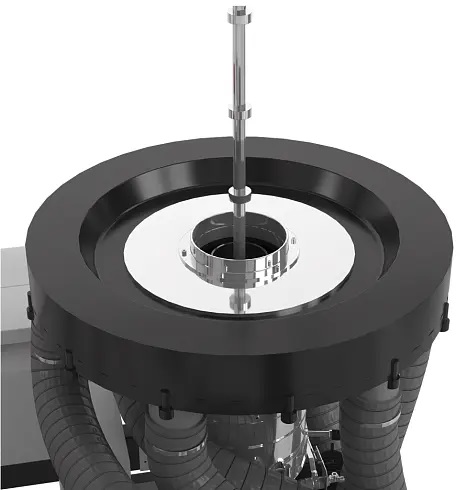

ABA ring type die head:

-

Working surface coated with hard chrome (coating thickness 30 µm)

Optimum polymer rheology

Short melt channels

Temperature maintenance

Working surface coated with hard chrome (coating thickness: 30 mcm)

Control system:

-

Implemented using a PLC controller

Heating elements control system is operating with PID control.

Control and diagnose might be managed by remote access

All electric motors have Delta inverter control.

Screws:

-

Compression type with two barrier zones and one mixing zone

Made of steel with bimetallic coating

Diameters: 45/55/65/65/75/90 at customer's option

Winder:

The device might be equipped with one post or two (back-to-back) posts. All winders are equipped with automatic roll removal, strain gauge control system and EPC or CPC system (optional)

| Model | 35/45 | 45/55 | 55/65 | |

|---|---|---|---|---|

|

Layer А (Outer and Inner) |

HDPE | HDPE | LDPE | LDPE |

|

Layer B ( Middle) |

HDPE/CaCO3/HDPE/Recycled PE | |||

|

Capacity, kg/h |

to 100 | HDPE: до 140 | LDPE: to 200 | to 300 |

|

Film thickness, mcm |

HDPE: 15-60 | LDPE: 20-200 | ||

|

Screw diameters, mm |

35+45 | 45+55 | 55+65 | |

|

Screw l:D ratio |

1/32 | |||

|

Layers ratio |

to 1/8/1 | |||

|

Filter Type |

Candle/valve | |||

|

Die head type |

stationary/with rotation | |||

|

Diameter of wind roll, mm |

to 500 | |||

|

Effective film width, mm |

800 | 800-1300 | 1500-2100 | |

|

Die head diameter, mm |

50-100 | 80-150 | 150-300 | 200-400 |

|

Vertical rotating turret |

- | option | ||

| Die gap, mm | 1,2-2,0 | |||

|

Height, m |

4,8 | 6,7/9,5 | 9,5-11,6 | |

|

Winder type |

Single post/ two-post |

|||

|

Roll removal |

Automatic/manual |

|||

|

Main motor power, kW |

11/18,5 | 18,5/30 | 30/45 | |

|

Power consumption, kW/h |

50 | 78 | 90 | |

|

kW consumption per 1 kg of production, kW/kg |

0,3-0,4 | |||

We recommend