Description

-

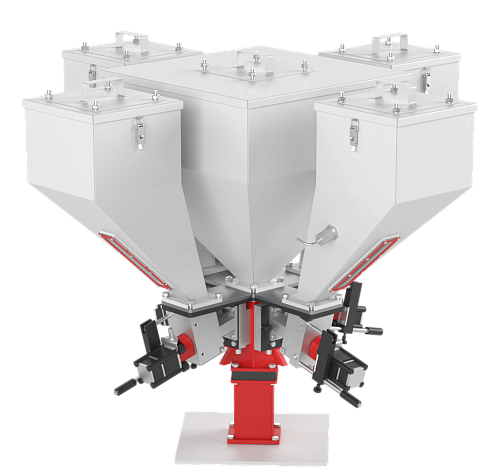

Equipment:

- Fine-tuning the recipe

- Each component is calibrated separately and can be adjusted to the specific type of material.

- Modularity

Feed hoppers are easy to add: the system can be transformed from 1+1 to 1+4.

- Easy to load

Isolated hoppers, adaptable to any type of loader - Stepper / induction motor

Allows a wide range of screw speed control - Raw material presence control:

- Raw material presence sensor

- Visual control of raw material presence via viewing window - Inclined / straight screw

The 15 degree angle of the augers allows for a more even material feed without pulsation. - Quick change of components after formula changing

Dumping holes allow complete removal of components from the hopper quickly - Memory up to 100 recipe

You can save up to 100 recipes in yhe dosing system memory

Characteristics

| Model | 0+1 | 1+1 | 1+2 | 1+3 | 1+4 |

|---|---|---|---|---|---|

| Motor stepper / induction , kWt | 1*0,03 / 1*0,09 | 1*0,03 / 1*0,09 | 2*0,03 / 2*0,09 | 3*0,03 / 3*0,09 | 4*0,03 / 4*0,09 |

| Production capacity (kg/h) | 0,06-40 | 0,06-40 | 0,12-80 | 0,18-120 | 0,24-160 |

| Volume of the main material hopper (l) | - | 100 | 100 | 100 | 100 |

|

Volume of the additional material hopper (l) |

22 | 22 | 22 | 22 | 22 |

| Dimensions L x W x H (mm) | 845*543*795 | 845*795*795 | 845*845*795 | 1130*1130*795 | 1130*1130*795 |

| Weight (kg) | 42 | 62 | 81 | 100 | 118 |

| Power | 220/380 V, 1 phase / 3phase | ||||